IRON WATCHDOG

Transforming Drilling with Smart Sensors and Cloud Integration

Transforming Drilling with Smart Sensors and Cloud Integration

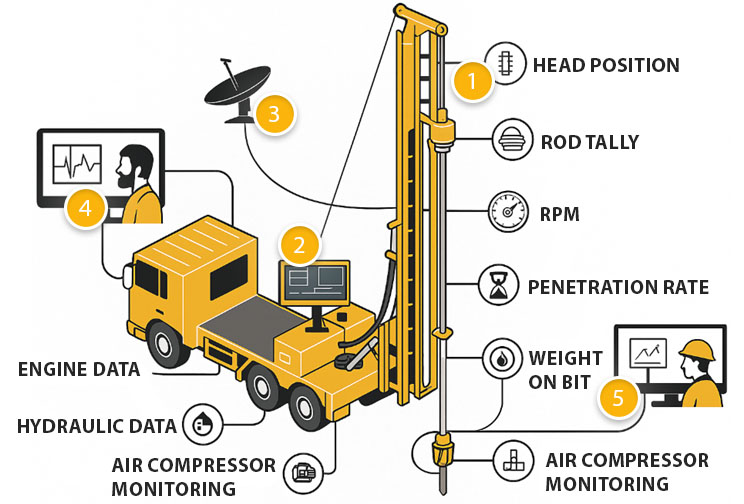

Retrofitted onto any drill

Robust system of sensors, instruments, mobile controllers, and touchscreen displays

All working together to provide real-time drill data for optimized operations in the mining and drilling industries

Access our web-based portal where data is collected, stored, and displayed seamlessly for instant insights

Built-in analytics enable faster decision-making, cross-functional collaboration, and operational efficiency

The rig is equipped and retrofitted with advanced smart sensors that continuously track critical drilling parameters in real time

These sensors are paired with an on-rig console that provides the driller with instant visibility, displaying actionable insights and performance indicators

Real-time data from the rig is seamlessly transmitted to the cloud, ensuring secure storage and global accessibility

Information is visualized in interactive dashboards and charts, making it easy to monitor performance and detect trends at a glance

Built-in analytics and reporting tools transform raw data into meaningful insights, enabling faster decision-making and operational optimization

Unlock faster drilling, reduced costs, improved safety, and scalability across rigs

Faster drilling cycles

Lower downtime

Operating efficiency

Faster drilling cycles through real-time monitoring and operating within optimal parameters

Prevent downtime through real-time insights, data visibility, cross-functional collaboration, and an "operate it right" approach

Lower energy costs, consumable usage (bits, mud, fuel), same footage with fewer shifts

Success factors to fully unlock benefits of the smart rig

To unlock the system’s full potential, we follow six principles: frontline adoption, scaling across multiple rigs, durable hardware, reliable technical infrastructure, and a continuous improvement mindset

Frontline adoption, combined with a data-driven culture, creates a faster pathway to results

Durable hardware built for harsh conditions and reliable infrastructure ensure uninterrupted data collection and analytics

Continuous improvement, powered by insights from multiple rigs, accelerates learning, benchmarking, and best-in-class operations

6 elements to fully unlock the potential of the smart rig

IWD delivers plug-and-play smart drilling technology with universal compatibility, zero upfront costs, and seamless integration into any rig type

Backed by an experienced team, we provide comprehensive training, interoperability with existing systems, and continuous innovation to maximize value

Easily installs on any exploration rig type (RC, diamond core, rotary, sonic)—no custom hardware overhauls needed, unlike rigid systems

No capital expense for hardware or installation; we handle it all

Backed by experts in drilling tech, ensuring reliable deployment and insights tailored to mining and exploration challenges

We train operators, mining clients, geologists, and all stakeholders for seamless integration—fostering buy-in and maximizing value from day one

Integrates effortlessly with existing datasets, tools, or third-party systems—avoiding the silos often seen in other platforms

Always evolving with cloud-based enhancements, predictive maintenance alerts, and AI-driven optimizations to keep your rigs ahead of the curve

4200 Research Forest STE 190, The Woodlands, TX 77381

info@ironwatchdog.com

+1 801 580 7444